Main Body Warranty

Auxiliary Warranty

Equipment Type

Other Support Unit Component

Movable Pump

Beer Hose

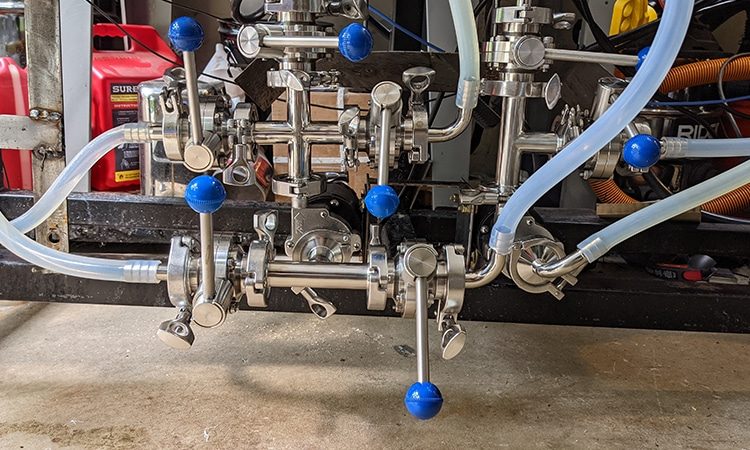

Manifold

Flow Meter

Advantages of Other Support Units

Reliability and Durability

ZYB Craft's commitment to quality craftsmanship means that our other support units are built to last. Using premium materials and robust construction techniques, our support units withstand the rigors of brewery operations, delivering reliable performance batch after batch.

Enhanced Efficiency

By integrating our other support units into your brewery system, you can streamline operations and optimize workflow. From the smooth transfer of liquids facilitated by our movable pump to the precise measurement provided by our flow meter, each component is engineered to minimize downtime and maximize productivity.

Improved Quality Control

Maintaining consistency and quality in brewing is paramount. Our other support units, such as the Manifold and flow meter, enable brewers to monitor and regulate various aspects of the brewing process with precision. This ensures that each batch meets your exacting standards, resulting in superior brews that delight your customers.

Customization

Our other support units are tailored to meet the specific needs and preferences of each customer. Whether you require a particular size, configuration, or functionality, we work closely with you to design and manufacture support units that align perfectly with your brewery setup.

Hygiene and Safety

Hygiene is critical in brewing to prevent contamination and maintain product integrity. Our beer hose is designed with hygiene in mind, utilizing materials that are easy to clean and resistant to bacterial growth, ensuring the purity of your brews. Additionally, our support units are engineered with safety features to protect both personnel and equipment during operation.

Versatility

Whether you're a small craft brewery or a large-scale production facility, our other support units are versatile enough to accommodate a wide range of brewing setups and processes. From manual to automated systems, our support units can be integrated seamlessly into your existing infrastructure, providing flexibility and adaptability as your brewery evolves.

Why Choose ZYB Craft

Customization Expertise

Quality Craftsmanship

Comprehensive Solutions

Exceptional Service

Get Other Support Unit Solutions

Frequently Asked Questions

Do Brewery Equipment Accessories Meet Specific Safety Features or Certifications?

Yes, brewery equipment accessories often need to meet specific safety features and certifications to ensure the safe operation of brewing equipment and comply with relevant regulations. Here are some common safety features and certifications that brewery equipment accessories may adhere to:

- Electrical Safety: Electrical accessories such as control panels, pumps or sensors should comply with electrical safety standards such as UL (Underwriters Laboratories) certification or CE (European Conformity) marking for the European market. These certifications ensure that equipment meets required safety and performance standards.

- Hygienic Design: Accessories that come into contact with the brewing process, such as valves, fittings, or hoses, should follow the principles of hygienic design. They should be made of food-grade materials, have smooth surfaces that are easy to clean, and be designed to minimize the risk of contamination or bacterial growth. Sanitary certification, such as 3-A Sanitary Standards or NSF International Certification, can show compliance with these requirements.

- Pressure And Temperature Ratings: Accessories involved in processes at high pressure or extreme temperatures, such as pressure relief valves or heat exchangers, should meet specific pressure and temperature ratings. These ratings ensure that the accessory will safely handle the operating conditions it faces, preventing potential failure or hazard.

- Material Compatibility: Brewery equipment accessories should be compatible with the substances they come into contact with, such as wort, beer, or cleaning agents. They should be resistant to corrosion, chemicals, and temperature changes. Compatibility with specific materials is often indicated by material certification, such as FDA (US Food and Drug Administration) approval for food-grade materials.

- Hazardous Location Considerations: In certain brewery environments, such as those with potentially explosive atmospheres or flammable liquids, fittings may need to meet specific hazardous location certifications, such as ATEX (Explosive Atmospheres) in Europe or NEC (National Electrical Appliances) in the US specification) standard status.

- Ergonomics And Operator Safety: Equipment accessories that require manual handling, such as hoses, clamps, or lifting devices, should consider ergonomic design principles to minimize the risk of operator strain or injury. They should be easy to handle, properly labeled, and have safety features such as ergonomic handles or quick-release mechanisms.

- Comply With Local Regulations: Depending on the location of the brewery, equipment accessories may need to meet specific local regulations and certifications. These may include specific safety standards, electrical codes, or other requirements set by local authorities or brewing trade associations.

- Calibration And Measurement Accuracy: Accessories involved in the measurement and control process, such as flow meters or temperature sensors, should meet the accuracy and calibration standards. Calibration certification, or traceability to recognized standards, ensures that accessories provide accurate measurements, allowing precise control and monitoring of the brewing process.

Brewery equipment accessories must meet these safety features and certifications to ensure the integrity of the brewing process, keep operators safe and comply with regulatory requirements. When selecting equipment accessories, it is advisable to consult the manufacturer for information on safety features, certifications, and compliance with relevant standards.

Are The Accessories Compatible With My Existing Brewery Equipment?

Compatibility of accessories with existing brewery equipment may vary based on a number of factors, including the specific accessory, the design and specification of the existing equipment, and any customization or retrofit requirements. Here are some notes about compatibility:

- Manufacturer Compatibility: Some brewery equipment manufacturers offer a range of accessories specifically designed to be compatible with their own equipment. If you’re sourcing accessories from the same manufacturer as your existing equipment, the chances of compatibility are higher because they’re designed to work together seamlessly.

- Standardized Connections: Many fittings such as pumps, valves and fittings are designed to follow industry standard connection sizes and types. This allows for easy interchangeability and compatibility with a wide variety of brewery equipment. Common connection standards include tri-clamp fittings, NPT (National Pipe Thread), BSP (British Standard Pipe), or specific manufacturer-specific connections.

- Customization And Retrofits: In some cases, it may be necessary to retrofit or retrofit existing equipment to ensure compatibility with certain accessories. This may involve adjusting or adding specific connections, valves or fittings to accommodate the attachment. Customization options may vary depending on the manufacturer and the nature of the accessory.

- Consult Your Device Manufacturer or Supplier: If you have specific accessories but are unsure of their compatibility with your existing device, it is recommended to consult the accessory manufacturer or your device supplier. They can provide guidance on compatibility, potential modifications needed, or suggest alternative accessories that are more compatible with your setup.

- Professional Assessment: For complex compatibility issues or when making major changes to brewery equipment, it may be helpful to hire a professional brewery equipment consultant or engineer. They can evaluate your existing equipment, review the specifications of required accessories, and provide expert advice on compatibility and any necessary modifications.

Ensuring compatibility between accessories and existing brewery equipment is critical to achieving seamless integration, optimizing performance and minimizing potential issues during operation. By working closely with accessory manufacturers, equipment suppliers or industry experts, you can understand compatibility considerations and make informed decisions for your brewery.

How Long Does It Take For Brewery Equipment Accessories To Be Delivered And Installed?

We will send accessories to customers within 48 hours after receiving customer needs. But delivery and installation times for brewery equipment accessories can vary based on a number of factors, including the specific accessory, its availability, customization requirements, and the logistics involved. Here are some considerations that may affect the time frame:

- Availability: Availability of accessories affects delivery times. If the parts are in stock, the lead time may be shorter than if the parts need to be produced or customized to meet specific requirements.

- Customization: If fittings need to be customized to fit your specific brewery equipment or process, additional time may be required for fabrication or modification. This can extend the overall delivery and installation time.

- Delivery Times And Order Processing: Our delivery times for processing orders and preparing accessories for shipment may vary. Typically, we communicate estimated delivery times and order processing procedures with our customers.

- Shipping And Logistics: Delivery times also depend on the shipping method and the distance between us and your brewery. Factors such as the carrier, method of transportation (air, ground, or ocean), and any customs processes (for international shipments) all affect overall delivery time.

- Installation Complexity: Installation time for accessories may vary depending on the complexity of the accessory and compatibility with existing equipment. Some accessories may require professional installation or coordination with a brewery technician, while others can be easily installed by your own brewing team.

If you want to determine the specific delivery and installation time of brewery equipment accessories, you can contact us at any time. We will provide you with an estimated timeline based on production capacity, current workload, and order specifics.

Do Brewery Equipment Accessories Need To Meet Any Unique or Custom Requirements of The Brewing Process?

Yes, brewery equipment accessories may need to meet unique or custom requirements specific to the brewing process. These requirements may vary depending on specific accessories and brew settings. Here are some common customization requirements to consider:

- Size And Fit: Fittings should be compatible with existing brewery equipment, including vessel size, connections, and layout. Customization may be required to ensure proper size and fit the specific configuration of the brewery.

- Material Compatibility: Accessories should be made of materials that are compatible with the brewing process and the liquids or chemicals it comes into contact with. Factors to consider include corrosion resistance, chemical compatibility, and compliance with food-grade or sanitary standards.

- Temperature And Pressure Ratings: Depending on the application, fittings may need to withstand specific temperature and pressure conditions. Custom requirements may include higher temperature resistance, pressure rating, or insulation to ensure safe and efficient operation.

- Integration With Control Systems: Accessories that interface with control systems or automation may need to meet specific integration requirements. This can include compatibility with communication protocols, sensors, or control interfaces to ensure seamless integration and efficient operation.

- Hygiene And Cleanability: Accessories that come into contact with beer or brewing ingredients must meet hygiene and cleanability requirements. Considerations may include smooth surfaces, ease of disassembly for cleaning, and compliance with hygiene standards and regulations.

- Process Flow And Integration: Brewery equipment accessories may require custom configuration or adjustments to integrate seamlessly into your brewing process. This includes considerations such as the positioning of valves, pumps, or sensors to optimize fluid flow, process monitoring, or automation.

- Safety Features: Custom requirements may include specific safety features such as pressure relief valves, temperature sensors, or interlocks to ensure safe operation and prevent accidents or equipment damage.

- Regulatory Compliance: Accessories may need to meet specific regulatory requirements, such as electrical safety certifications, food safety regulations, or environmental standards. Compliance with these regulations may require customization or adherence to specific guidelines.

- Sustainability And Efficiency: Custom requests may include features or design elements that enhance sustainability, energy efficiency, or water conservation. This can include components for waste reduction, energy recovery, or improved process efficiency.

When purchasing brewery equipment accessories, you can communicate your unique requirements and brewing process details to us. We can provide guidance on selecting or customizing accessories to meet the specific needs of your brewing process, ensuring compatibility, functionality, and optimal performance of your brewery setup.

Are There Any Specific Quality Control or Testing Requirements For Brewery Equipment Accessories?

Yes, brewery equipment accessories often have specific quality control and testing requirements to ensure their performance, safety, and compliance with industry standards. Here are some common quality control and testing considerations for brewery equipment accessories:

- Material Quality: The materials used in manufacturing equipment accessories shall comply with relevant quality standards and specifications. This includes ensuring the material is food-grade, corrosion-resistant, durable, and suitable for the intended application in the brewery environment.

- Performance Testing: Equipment accessories may be subjected to performance testing to verify their functionality, reliability, and performance under expected operating conditions. This may involve testing factors such as flow rates, pressure ratings, temperature resistance, and compatibility with specific fluids or brewing ingredients.

- Compatibility Testing: Brewery equipment accessories should be tested for compatibility with other brewing equipment and processes. This includes verifying proper installation, connection compatibility, and integration with existing equipment such as valves, pumps, hoses, or control systems.

- Safety Testing: Accessories involving electrical components or systems should be safety tested to ensure compliance with applicable electrical safety standards. This includes insulation, grounding, testing against electric shock, and compliance with relevant safety certifications.

- Sanitation And Cleanability: Fittings that come into contact with brewing ingredients or liquids shall be designed and tested for ease of cleaning and sanitation. They should be resistant to microbial growth, have an easy-to-clean smooth surface, and be able to withstand standard cleaners and processes.

- Compliance With Regulations: Brewery equipment accessories should comply with relevant industry regulations and standards, including those related to food safety, hygiene, electrical safety, and environmental factors. Depending on the region and application, compliance with certifications such as NSF (National Sanitation Foundation), FDA (Food and Drug Administration) or CE (European Conformity) may be required.

- Quality Assurance Process: Manufacturers should have a robust quality assurance process in place, which may include inspections, standardized production procedures, traceability of materials, and comprehensive testing protocols. These processes ensure consistent quality and help identify any potential issues before parts are shipped to customers.

Manufacturers of brewery equipment usually have quality control systems in place to ensure their accessories meet these requirements. They can conduct in-house testing, work with third-party testing labs, or follow specific industry standards and guidelines to ensure the quality and performance of their accessories. Customers can inquire about the quality control and testing procedures implemented by the manufacturer to gain confidence in the reliability and compliance of the parts.