Main Body Warranty

Auxiliary Warranty

Equipment Type

Grain Handling System Components

Stainless Steel Malt Mill

Automated Grain Handling System

Special Material-Water Mixer

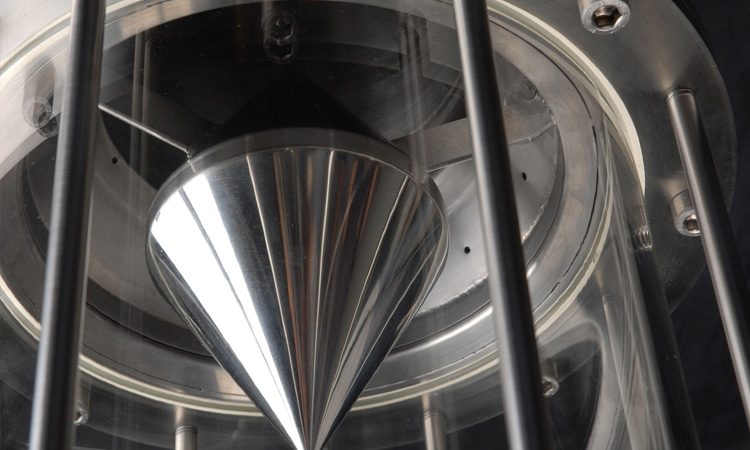

Specially Designed Pre-Masher

Advantages of Grain Handling System

Precision and Consistency

Grain handling systems ensure precise control over the entire grain handling process, from milling to mashing. This precision results in consistent grain milling, hydration, and mashing, leading to repeatable brewing outcomes and high-quality beer production.

Labor Efficiency

By automating grain handling tasks such as transportation, milling, and mixing, these systems reduce the need for manual labor. Brewers can allocate their resources more efficiently, focusing on other aspects of the brewing process while the system handles repetitive tasks with minimal human intervention.

Time Savings

Grain handling systems streamline the brewing process by reducing the time required for grain preparation. Automated systems can handle large quantities of grains swiftly and efficiently, speeding up the overall brewing cycle and increasing brewery productivity.

Improved Hygiene and Safety

With components crafted from materials like stainless steel, grain handling systems prioritize hygiene and safety in the brewery environment. Sanitary design features minimize the risk of contamination, ensuring the integrity of the brewing process and the quality of the final product.

Customization and Adaptability

Grain handling systems from ZYB Craft are custom-designed to meet the specific needs and preferences of each brewery. Whether it's adjusting milling settings or integrating additional components, these systems offer flexibility and adaptability to accommodate various brewing styles and recipes.

Enhanced Quality Control

By providing brewers with greater control over grain handling parameters, these systems contribute to enhanced quality control throughout the brewing process. Brewers can monitor and adjust variables such as grain particle size and water-to-grain ratio, ensuring optimal conditions for achieving desired flavors and characteristics in the final beer.

Why Choose ZYB Craft

Manufacturing Expertise

Exceptional Quality and Durability

Advanced Technology and Innovation

Comprehensive Support and Service

Get Grain Handling System Solutions

Frequently Asked Questions

What Is Beer Grain Handling Equipment?

Beer grain handling equipment refers to the machinery and tools used by breweries to handle, process, and store grains (mainly barley, the key ingredient in beer production). This equipment facilitates the efficient movement and handling of grain throughout the brewing process. Here are some common types of beer grain handling equipment:

- Grain Silo: Grain silos are large storage containers used to hold large quantities of malt. Silos vary in size and capacity, allowing breweries to store and manage their grain stocks conveniently. They usually have temperature and humidity control systems to maintain optimal conditions for grain storage.

- Grain Mill/Malt Mill: Grain mills, also known as malt mills, are used to crush or grind malted barley into smaller particles called malt flour. This process exposes the starches inside the grains, facilitating the extraction of fermentable sugars during mashing. Grain mills can be manually operated or driven by an electric motor and come in a variety of designs, such as roller mills or hammer mills.

- Conveyors: Conveyors are used to transport grain within a brewery, facilitating the movement of barley malt from grain storage areas to other processing equipment. Depending on the specific needs and layout of the brewery, belt conveyors, screw conveyors or pneumatic conveyors can be used.

- Grain Hopper: A grain hopper is a container that receives and temporarily stores grain before it enters the brewing process. Hoppers can be equipped with level sensors or weight scales to monitor and control the amount of grain added to the brewing system.

- Grain Screw Conveyor: Grain screw conveyors, also called grain elevators, are mechanical devices that help transport grain vertically or horizontally. They are often used to move grain between different levels of a brewery, for example from the ground to the top of a silo or from one processing stage to another.

- Grain Handling Systems: Grain handling systems include a variety of equipment and components that automatically move and handle grain. These systems may include grain elevators, bucket elevators, pneumatic conveyance systems, and automated controls to simplify the grain handling process, increase efficiency, and reduce manual labor.

- Grain Dedusting Systems: Grain dedusting systems are critical to maintaining a clean and safe working environment in breweries. These systems utilize filters and fans to capture and remove airborne grain dust produced during milling or grain handling, reducing the risk of breathing problems or fire hazards.

Efficient grain handling equipment is essential for breweries to ensure a constant supply, proper handling, and efficient use of barley malt in the brewing process. These tools and machinery contribute to the overall productivity and quality of beer production by optimizing the handling and processing of grain.

What Is The Process of Grain Handling In Brewing Beer?

Grain handling in beer brewing involves a series of steps from receiving malted grain to preparing it for the mashing process. Here is an overview of the grain handling process during brewing:

- Grain Shipping And Storage: Malted grain (usually barley) is shipped to the brewery in bags or bulk containers. Grain is checked for quality, including factors such as moisture content, appearance, and potential contaminants. They are then stored in a granary or dedicated storage area.

- Grinding/Crushing: Before mashing, the malted grain needs to be ground or crushed to expose the starchy interior. This process increases the surface area of the grains, allowing for better extraction of sugars during mashing. The grain is fed into a grain mill or crusher, which breaks it down to the desired consistency. The crushed grain (called grist) is collected in the grain hopper.

- Grain In The Mash Tun: Wheat flour is transferred from the grain hopper into the mash tun, which is the vessel in which mashing takes place. Mix the grits with hot water to start the mashing process. The hot water activates enzymes in the grains that convert starches into fermentable sugars.

- Mash Rest: A mixture of mash and water (called the mash) is left at a range of temperatures to promote enzyme activity and extract sugars. Different temperature rests target specific enzymes to optimize the conversion of starch to sugar. The mash usually goes through resting processes such as protein resting, mashing resting, and mashing resting.

- Filtration: After the mash has settled, filtration begins. Filtration involves separating the liquid part (called the wort) from the stillage. The mash is transferred to a lauter tun where the wort is separated by rinsing the grains with hot water. This process extracts as much sugar as possible from the grain bed.

- Lees Removal: After the wort has been separated, the grains (called dregs or grains) are removed from the lauter tun. They are often collected and reused, for example as animal feed, composted, or used to produce other food products.

- Wort Boiling: The wort collected by filtration is transferred to a brew pot and boiled. At this stage, hops are often added to provide bitterness, aroma, and flavor to the beer. The boiling process also sanitizes the wort, further extracts hop compounds, and helps concentrate the liquid.

- Cooling And Fermentation: After boiling, the wort needs to be cooled quickly to the desired fermentation temperature. Various cooling methods, such as plate heat exchangers or immersion coolers, are used to reduce the wort temperature. After cooling, the wort is transferred to fermentation vessels, where yeast is added for fermentation, converting the sugars to alcohol and carbon dioxide.

Maintaining cleanliness and quality control throughout the grain handling process is critical to ensuring the production of high-quality beer. Each step helps extract sugars, flavors, and other desired compounds from the grains, setting the stage for subsequent stages of brewing.

How Is The Grain Prepared For Winemaking?

The grain (usually barley) used to brew beer goes through a series of steps to prepare it for the brewing process. The preparation of grain includes cleaning, malting, and grinding. Here is a detailed description of the cereal preparation process:

- Cleaning: Once the grain arrives at the brewery, it goes through a cleaning process to remove any impurities, foreign matter, or damaged grain. This step is critical to ensuring the quality and purity of the grain.

- Malting: Malting is a critical step in the preparation of brewing grains. Malting involves soaking grains in water and allowing them to germinate under controlled conditions. During sprouting, enzymes within the grain are activated to convert the grain’s starches into fermentable sugars. Grains are carefully monitored and turned regularly to prevent overgrowth and ensure even germination.

- Drying: After germination, the malt is transferred to kilns to dry. The drying process prevents germination by applying controlled heat to the grain. This step not only stops enzyme activity but also imparts flavor and color to the malt. Different roasting temperatures and durations result in different types of malts, such as pale, crystal, or roasted malts, each of which brings a different character to the beer.

- Modification: In addition to malting and drying, grains may also undergo a modification process. The modification involves controlling the degree of enzymatic activity during the malting process to achieve specific malt characteristics. Highly modified malts have a higher enzyme potential, while low-modified malts have lower enzyme levels. Brewers choose varying degrees of modified malts based on their desired beer style and specific enzymatic requirements.

- Cracking/Grinding: Malted grains are cracked or ground before being used in the brewing process. Crushing breaks up the grains, exposing the starchy interior. This effectively extracts the sugar during mashing, the next step in the brewing process. The coarseness of the comminution can be adjusted to achieve the desired particle size and optimize sugar extraction.

- Packaging And Storage: Once the barley malt is prepared and crushed, it is usually packaged in bags, or containers, or shipped in bulk to the brewery. Proper packaging and storage conditions, such as temperature and humidity control, are critical to maintaining the quality and freshness of the malt until it is ready for brewing.

The preparation of grains (especially malted barley) is crucial to release the starches and enzymes needed for the mashing process. The quality, flavor, and character of the malt greatly influence the final beer product. Brewers may also include other grains, such as wheat, rye, oats, or corn, which may have their own specific preparation or modification to suit the desired style of beer.

How Do Breweries Handle Distiller Grains?

There are a number of ways breweries can dispose of distiller’s grains, a by-product of the distillation process in spirits production. Distiller grains are the residue left after the fermentation and distillation of grains such as corn, barley, or wheat, used to produce spirits such as whiskey or vodka. These grains still retain nutritional value and can be repurposed for various applications. Here are some common ways breweries dispose of their grains:

- Animal Feed: One of the main uses of distiller grains is animal feed. Due to their high protein and nutrient content, distiller grains can be an excellent source of animal feed for livestock, including cattle, pigs, and poultry. Breweries can partner with local farmers or feed companies to provide them with distillers grains for animal feed.

- Compost: Distiller grains can be used as an ingredient in compost. Combined with other organic materials such as food waste or yard scraps, distiller grains can provide valuable nutrients to the compost pile. The compost mixture can then be used as a fertilizer for gardening, landscaping, or agricultural purposes.

- Biogas Production: In some cases, breweries with the necessary infrastructure may use waste grain to produce biogas. Distillers grains can be added to an anaerobic digester, where they undergo a process of converting organic material into biogas, which can then be used for energy production or other applications.

- Value-Added Products: Some breweries are exploring value-added options for their distillers’ grains. They might partner with local food producers to produce products like waste-grain bread, crackers, or granola bars. Distiller grains can also be used to produce non-alcoholic beverages, such as kombucha or craft soda. These value-added products help reduce waste and create an additional revenue stream for the brewery.

- Wet/Dry Storage: Breweries that produce large quantities of distiller grains can store them for later use or distribution. Wet storage involves keeping grain in a damp or wet state, usually in boxes or tanks, to prevent spoilage. Dry storage involves drying grain to reduce moisture content and extend its shelf life before storing it in silos or containers.

It is important to note that distiller grains should be handled in accordance with local regulations and guidelines to ensure proper storage, transport, and use. Breweries that produce distiller’s grain as a by-product of the distillation process can explore these options to repurpose and recycle grain, minimize waste and find alternative uses for the material.